- HOME

- Machinery & Rolls Division

- Production Facilities

High-precision ground calender rolls for the production of high accuracy, high quality films

Calendering is generally carried out at high temperatures.Heating rolls that were polished at room temperature (cold polish) to such high temperature can lead to generation of thermal distortions such as abnormal deformation of roll cylindricity (thermal crowning), errors in out of roundness and concentricity of rolls (rotational runout of rolls) and can cause thickness errors in the profile direction and machine direction of calender films.To remove these errors, in the hot grind process, the roll is heated to the same temperature as during the forming process, and the thermal deformations generated in the roll are removed by machining, making it possible to produce high accuracy, high quality calender films.

Applications

- ・Rolls for laminating, coating

- ・Rolls for calendering, embossing, printing

- ・Rolls for precision heat forming (wrap film, building materials, wall papers, liquid crystals, recording media, lithium-ion batteries, printed circuit boards, electrical and electronic materials, etc.)

Advantages of hot grinding

Removal of thermal crowns, resulting in

- ・Improved film profile thickness accuracy

- ・Expansion of effective working length and area of calender rolls

Improved roll rotational run-out accuracy, resulting in

- ・Improved film thickness accuracy in the machine direction

Economic effect of hot grinding

Reduction of raw material loss due to improved film accuracy

- ・Because of improved film thickness accuracy in the profile and machine directions, calenders that adopt hot ground rolls can save several hundred tons of raw materials annually.

Reduction of failure in secondary fabrication processes

- ・Furthermore, in lamination processes, and embossing processes, etc. the failure stemming from thickness errors in film during subsequent converting processes can be reduced exponentially.

・Equipment in Grind Shop

| Process machinery | Processing size | Number | Manufacture name | |

|---|---|---|---|---|

| Factory B | CNC Roll Grinder(Large) | ⌀1,400×8,000L | 1 | Waldrich Siegen GmbH & Co. KG |

| ⌀1,000×9,500 | 1 | Shibaura Machine Co., Ltd. | ||

| Crane | 20t | 2 | Nippon Hoist Co., Ltd. | |

| 1.4t | 3 | Nippon Hoist Co., Ltd. |

Always in sync with technological advances with products from the "company that delivers technology" - Nippon Roll

Our mixing and calendering machines as well as rolling mills, produced by our highly skilled production team and our wide range of high-performance production facilities including large-scale high-precision machines, claim a major share not only in Japan, but throughout the world.

Machine Shop A

Outside View

Outside View Interior View

Interior View

Machine Shop B

Outside View

Outside View Interior View

Interior View WALDRICHSIEGEN WSIVHK25x8.000

WALDRICHSIEGEN WSIVHK25x8.000 Toshiba Machines Roll Grinder KWA-1095D

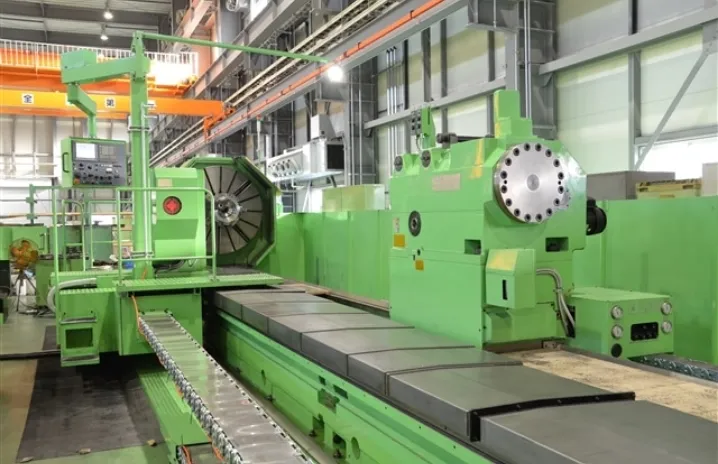

Toshiba Machines Roll Grinder KWA-1095D Self-Manufactured Universal Lathe

Self-Manufactured Universal Lathe

Machine Shop C

Outside View

Outside View Interior View

Interior View DAINICHI DLX95×5,000

DAINICHI DLX95×5,000 DAINICHI DLX75×2,000

DAINICHI DLX75×2,000 KURODA-JL JK-206ACD

KURODA-JL JK-206ACD Yamazaki-Kenkyu YZ-500SG X1052 Y552

Yamazaki-Kenkyu YZ-500SG X1052 Y552 DAINICHI W16R×10,000

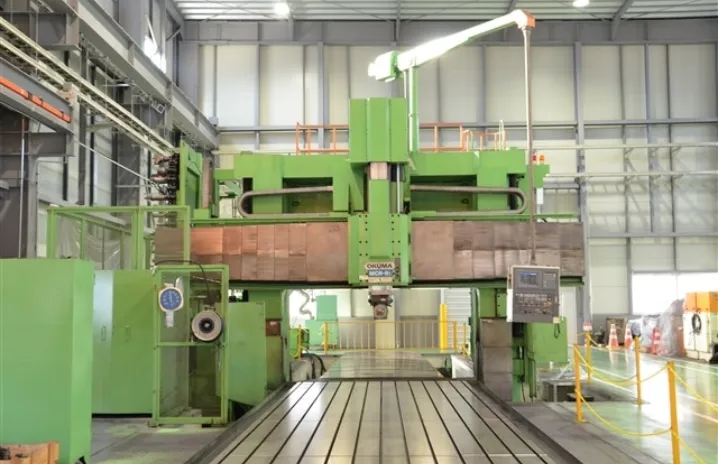

DAINICHI W16R×10,000 Ohkuma MCR-BⅡ 2,500×8,000

Ohkuma MCR-BⅡ 2,500×8,000 Toshiba Machines MPB 3560A 3,000×6,000

Toshiba Machines MPB 3560A 3,000×6,000

・Overview of Machine Tools

| Process machinery | Processing size | Number | Manufacture name | |

|---|---|---|---|---|

| Factory A | Roll Grinder (Large) | ⌀1,000×7,000L | 1 | Niigata Engineering Co., Ltd. |

| Plano Drilling Machine | 3,550W×6,000L | 1 | Shin Nippon Koki Co., Ltd. | |

| Lathe (Large) | ⌀1,060×6,000L | 1 | Ikegai Corp | |

| Lathe (Small) | ⌀400×1,600 | 1 | Yamazaki Mazak Corporation | |

| Crane | 20t | 1 | Nippon Hoist Co., Ltd. | |

| 10t | 1 | Nippon Hoist Co., Ltd. | ||

| Factory B | CNC Roll Grinder(Large) | ⌀1,400×8,000L | 1 | Waldrich Siegen GmbH & Co. KG |

| ⌀1,000×9,500 | 1 | Shibaura Machine Co., Ltd. | ||

| Crane | 20t | 1 | Nippon Hoist Co., Ltd. | |

| 10t | 1 | Nippon Hoist Co., Ltd. | ||

| Factory C | Double-Column 5-Axis Machining Center | 3,000W×8,000L | 1 | Okuma Corporation |

| Double-Column 5-Axis Machining Center | 3,550W×6,000L | 1 | Shibaura Machine Co., Ltd. | |

| CNC Lathe | ⌀1,400×10,000 | 1 | Dainichi Kinzoku Kogyo Co., Ltd | |

| ⌀250×1,000L | 1 | DMG Mori Co., Ltd. | ||

| 75×2,000L(⌀400) | 1 | Dainichi Kinzoku Kogyo Co., Ltd | ||

| 95×5,000L(⌀700) | 1 | Dainichi Kinzoku Kogyo Co., Ltd | ||

| Milling Machine | 500×1,600 | 1 | Yamasaki Giken Co., Ltd. | |

| Surface Grinding Machine | 600×2,000 | 1 | Kuroda Precision Industries Ltd. | |

| Drilling Machine | 2,580×1,050 | 1 | Ohtori-Kiko Co., Ltd. | |

| Crane | 2.8t | 3 | Nippon Hoist Co., Ltd. | |

| 30t | 1 | Nippon Hoist Co., Ltd. | ||

| 20t | 2 | Nippon Hoist Co., Ltd. |

Inquiries to the Machinery Roll Business Division

If you have any questions or inquiries about the Machinery Roll Business Division, please feel free to contact us.

- Inquiries via WebTo the Inquiry Form

- Inquiries by Phone03-3878-6661Reception hours / Weekdays 9:00 AM to 5:00 PM